Wasp Barcode Technologies: The Barcode Solution People

New Printable RFID Chip Could Greatly Reduce Costs

The industry hasn't seen the adoption rate of

RFID technology that we were expecting so many years ago. Why was that? You'd think with it being pushed through compliance initiatives by the United States' Department of Defense and a giant, nationwide retailer like Walmart that RFID would have taken off in no time. Thousands of manufacturers would have to be RFID compliant or lose a huge client. Surely, the laws of supply and demand would eventually kick in and the high cost of RFID equipment, software, and tags would be driven down, competition amongst RFID manufacturers would flare up, and advancements in the technology would come as quickly as they do for the rest of the AIDC industry. Instead, RFID technology is still a hefty investment and even Walmart has backed off on their compliance initiative. It seemed that RFID would not be a practical solution for retail...until now.

The latest technology breakthrough as reported in the March issue of the journal

IEEE Transactions on Electron Devices came from teams at

Sunchon National University in Korea and

Rice University that worked together to come up with an inexpensive, printable RFID transmitter that can be invisibly embedded in packaging. As opposed to the current RFID tags, which are largely silicon-based, the new technology is based on a carbon-nanotube-infused ink for ink-jet printers used to make thin-film transistors, a key element in RFID tags, that can be printed on paper or plastic.

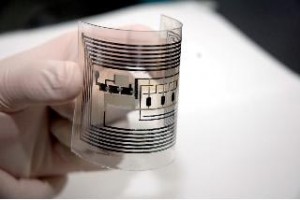

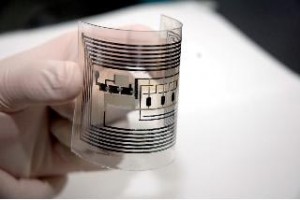

[caption id="attachment_337" align="alignright" width="300"]

Professor Gyou-jin Cho and his team at Sunchon National University are working on a roll-to-roll printing process that could bring the cost down to 1 cent per tag and eventually replace barcode labels on products.[/caption]

Professor Gyou-jin Cho at Sunchon foresees the technology to mature in five years. Cho and his team are also working on the roll-to-roll printing process, which uses a gravure process rather than ink-jet printers. He expects it will bring the cost of printing RFID tags down from the current 7 cents per tag to a 1 cent each and eventually replace the UPC barcodes on every product. Right now they have been able to create only one-bit tags, including the antenna, electrodes and dielectric layers, on plastic foil, which holds just enough information to give the RFID reader a yes or no response. Cho's lab is working on 16-bit tags that would hold a more practical amount of information and be printable on paper as well.

The other challenge they must overcome is getting the size of the RIFD tag down to the size of a typical UPC barcode. The one they've created so far is about three times that size. Its range must increase as well. "Right now, the emitter has to be pretty close to the tags, but it's getting farther all the time," Professor James Tour at Rice said. "The practical distance to have it ring up all the items in your shopping cart is a meter. But the ultimate would be to signal and get immediate response back from every item in your store - what's on the shelves, their dates, everything. At 300 meters, you're set - you have real-time information on every item in a warehouse. If something falls behind a shelf, you know about it. If a product is about to expire, you know to move it to the front - or to the bargain bin."

Tour also addressed the environmental concerns about putting nanotubes in packaging. "The amount of nanotubes in an RFID tag is probably less than a picogram. That means you can produce one trillion of them from a gram of nanotubes - a miniscule amount. Our HiPco reactor produces a gram of nanotubes an hour, and that would be enough to handle every item in every Walmart. In fact, more nanotubes occur naturally in the environment, so it's not even fair to say the risk is minimal. It's infinitesimal."

If Rice and Sunchon are successful, this could have a large impact on the industry. Of course, printer manufacturers would have to keep in step and be able to offer reasonably-priced printers that can create these new RFID tags. It would do very little good to the bottom line for the tag price to be reduced 85% if the price of the printer is five times as much, to give an example. Also, retailers would have to be willing to install the RFID readers and compatible point-of-sale and inventory systems in their stores. It's natural to assume that there'd be a period of time where the barcode and RFID technologies overlap in the retail environment as manufacturers and retailers work to switch their systems. That could be quite difficult for the biggest manufacturers, who may have many large maufacturing facilities, and for the small business owners, who may not have the resources to implement costly technology. This new RFID technology may mature in five years as Cho predicts, but it could be a decade or more after that before we see it as the primary method of product identification. Just look at how often the Sunrise initiative from GS1 (formerly UCC and EAN) for the standardized use of 2D barcodes in retail has been pushed back.

Professor Gyou-jin Cho and his team at Sunchon National University are working on a roll-to-roll printing process that could bring the cost down to 1 cent per tag and eventually replace barcode labels on products.[/caption]

Professor Gyou-jin Cho at Sunchon foresees the technology to mature in five years. Cho and his team are also working on the roll-to-roll printing process, which uses a gravure process rather than ink-jet printers. He expects it will bring the cost of printing RFID tags down from the current 7 cents per tag to a 1 cent each and eventually replace the UPC barcodes on every product. Right now they have been able to create only one-bit tags, including the antenna, electrodes and dielectric layers, on plastic foil, which holds just enough information to give the RFID reader a yes or no response. Cho's lab is working on 16-bit tags that would hold a more practical amount of information and be printable on paper as well.

The other challenge they must overcome is getting the size of the RIFD tag down to the size of a typical UPC barcode. The one they've created so far is about three times that size. Its range must increase as well. "Right now, the emitter has to be pretty close to the tags, but it's getting farther all the time," Professor James Tour at Rice said. "The practical distance to have it ring up all the items in your shopping cart is a meter. But the ultimate would be to signal and get immediate response back from every item in your store - what's on the shelves, their dates, everything. At 300 meters, you're set - you have real-time information on every item in a warehouse. If something falls behind a shelf, you know about it. If a product is about to expire, you know to move it to the front - or to the bargain bin."

Tour also addressed the environmental concerns about putting nanotubes in packaging. "The amount of nanotubes in an RFID tag is probably less than a picogram. That means you can produce one trillion of them from a gram of nanotubes - a miniscule amount. Our HiPco reactor produces a gram of nanotubes an hour, and that would be enough to handle every item in every Walmart. In fact, more nanotubes occur naturally in the environment, so it's not even fair to say the risk is minimal. It's infinitesimal."

If Rice and Sunchon are successful, this could have a large impact on the industry. Of course, printer manufacturers would have to keep in step and be able to offer reasonably-priced printers that can create these new RFID tags. It would do very little good to the bottom line for the tag price to be reduced 85% if the price of the printer is five times as much, to give an example. Also, retailers would have to be willing to install the RFID readers and compatible point-of-sale and inventory systems in their stores. It's natural to assume that there'd be a period of time where the barcode and RFID technologies overlap in the retail environment as manufacturers and retailers work to switch their systems. That could be quite difficult for the biggest manufacturers, who may have many large maufacturing facilities, and for the small business owners, who may not have the resources to implement costly technology. This new RFID technology may mature in five years as Cho predicts, but it could be a decade or more after that before we see it as the primary method of product identification. Just look at how often the Sunrise initiative from GS1 (formerly UCC and EAN) for the standardized use of 2D barcodes in retail has been pushed back.

Professor Gyou-jin Cho and his team at Sunchon National University are working on a roll-to-roll printing process that could bring the cost down to 1 cent per tag and eventually replace barcode labels on products.[/caption]

Professor Gyou-jin Cho at Sunchon foresees the technology to mature in five years. Cho and his team are also working on the roll-to-roll printing process, which uses a gravure process rather than ink-jet printers. He expects it will bring the cost of printing RFID tags down from the current 7 cents per tag to a 1 cent each and eventually replace the UPC barcodes on every product. Right now they have been able to create only one-bit tags, including the antenna, electrodes and dielectric layers, on plastic foil, which holds just enough information to give the RFID reader a yes or no response. Cho's lab is working on 16-bit tags that would hold a more practical amount of information and be printable on paper as well.

The other challenge they must overcome is getting the size of the RIFD tag down to the size of a typical UPC barcode. The one they've created so far is about three times that size. Its range must increase as well. "Right now, the emitter has to be pretty close to the tags, but it's getting farther all the time," Professor James Tour at Rice said. "The practical distance to have it ring up all the items in your shopping cart is a meter. But the ultimate would be to signal and get immediate response back from every item in your store - what's on the shelves, their dates, everything. At 300 meters, you're set - you have real-time information on every item in a warehouse. If something falls behind a shelf, you know about it. If a product is about to expire, you know to move it to the front - or to the bargain bin."

Tour also addressed the environmental concerns about putting nanotubes in packaging. "The amount of nanotubes in an RFID tag is probably less than a picogram. That means you can produce one trillion of them from a gram of nanotubes - a miniscule amount. Our HiPco reactor produces a gram of nanotubes an hour, and that would be enough to handle every item in every Walmart. In fact, more nanotubes occur naturally in the environment, so it's not even fair to say the risk is minimal. It's infinitesimal."

If Rice and Sunchon are successful, this could have a large impact on the industry. Of course, printer manufacturers would have to keep in step and be able to offer reasonably-priced printers that can create these new RFID tags. It would do very little good to the bottom line for the tag price to be reduced 85% if the price of the printer is five times as much, to give an example. Also, retailers would have to be willing to install the RFID readers and compatible point-of-sale and inventory systems in their stores. It's natural to assume that there'd be a period of time where the barcode and RFID technologies overlap in the retail environment as manufacturers and retailers work to switch their systems. That could be quite difficult for the biggest manufacturers, who may have many large maufacturing facilities, and for the small business owners, who may not have the resources to implement costly technology. This new RFID technology may mature in five years as Cho predicts, but it could be a decade or more after that before we see it as the primary method of product identification. Just look at how often the Sunrise initiative from GS1 (formerly UCC and EAN) for the standardized use of 2D barcodes in retail has been pushed back.